Tables for selecting the cable cross-section by power - Calculation of copper and aluminum cable by cross-sectional area

Selection tables for the cross-section of aluminum (Al) cable based on power, diameter, and voltage

Cross-Section of Conductor (Al) mm2 |

For cables with aluminum (Al) conductors |

|||

|---|---|---|---|---|

| Voltage 220 V | Voltage 380 V | |||

| Power kW | Current A |

Power kW |

Current A | |

| 2.5 | 4.4 |

20 | 12.5 |

19 |

| 4 | 6.1 |

28 | 15.1 |

23 |

| 6 | 7.9 |

36 | 19.8 |

30 |

| 10 | 11 |

50 | 25.7 |

39 |

| 16 | 13.2 |

60 | 36.3 |

55 |

| 25 | 18.7 |

85 | 46.2 |

70 |

| 35 | 22 |

100 | 56.1 | 85 |

| 50 | 29.7 |

135 | 72.6 |

110 |

| 70 | 36.3 |

165 | 92.4 |

140 |

| 95 | 44 | 200 |

112.2 |

170 |

| 120 | 50.6 | 230 |

132 |

200 |

Selection tables for the cross-section of copper (Cu) cable based on power, diameter, and voltage

| Cross-Section of Conductor (Cu) mm2 | For cables with copper (Cu) conductors |

|||

|---|---|---|---|---|

| Voltage 220 V | Voltage 380 V | |||

| Power kW | Current A |

Power kW |

Current A | |

| 1.5 | 4.1 | 19 |

10.5 |

16 |

| 2.5 | 5.9 |

27 | 16.5 |

25 |

| 4 | 8.3 |

38 | 19.8 |

30 |

| 6 | 10.1 |

46 | 26.4 |

40 |

| 10 | 15.4 |

70 | 33 |

50 |

| 16 | 18.7 |

85 | 49.5 |

75 |

| 25 | 25.3 |

115 | 59.4 |

90 |

| 35 | 29.7 | 135 |

75.9 |

115 |

| 50 | 38.5 |

175 | 95.7 |

145 |

| 70 | 47.3 |

215 | 118.8 |

180 |

| 95 | 57.2 |

260 | 145.2 |

220 |

| 120 | 66.9 |

305 | 169.4 |

255 |

Step 1: Determine the power consumption The first step in calculating the diameter (cross-sectional area) of copper or aluminum cable based on power is to determine the power consumed by the electrical load. This can be one or several electrical devices operating simultaneously. Power is usually specified in watts (W).

Step 2: Consider voltage and line length The next step is to consider the voltage at which the electrical load will operate and the length of the line through which the electrical energy will be transmitted. These parameters affect the magnitude of power losses in the line, which must be taken into account when selecting the diameter (cross-sectional area) of the cable.

Step 3: Determine the allowable voltage drop The allowable voltage drop is one of the key parameters that must be considered when selecting the diameter (cross-sectional area) of the cable. Usually, the allowable voltage drop is not more than 3-5% of the nominal line voltage.

Step 4: Use tables and formulas After determining the power, voltage, line length, and allowable voltage drop, you can proceed to use tables and formulas.

Choosing the correct cable cross-section plays an important role in ensuring the efficient operation of electrical equipment. To select the appropriate cable cross-section, factors such as equipment power, line length, and allowable voltage drop need to be taken into account.

To facilitate this task, cable cross-section selection tables based on power have been developed. These tables allow for quickly determining the required cable cross-section for various types of equipment.

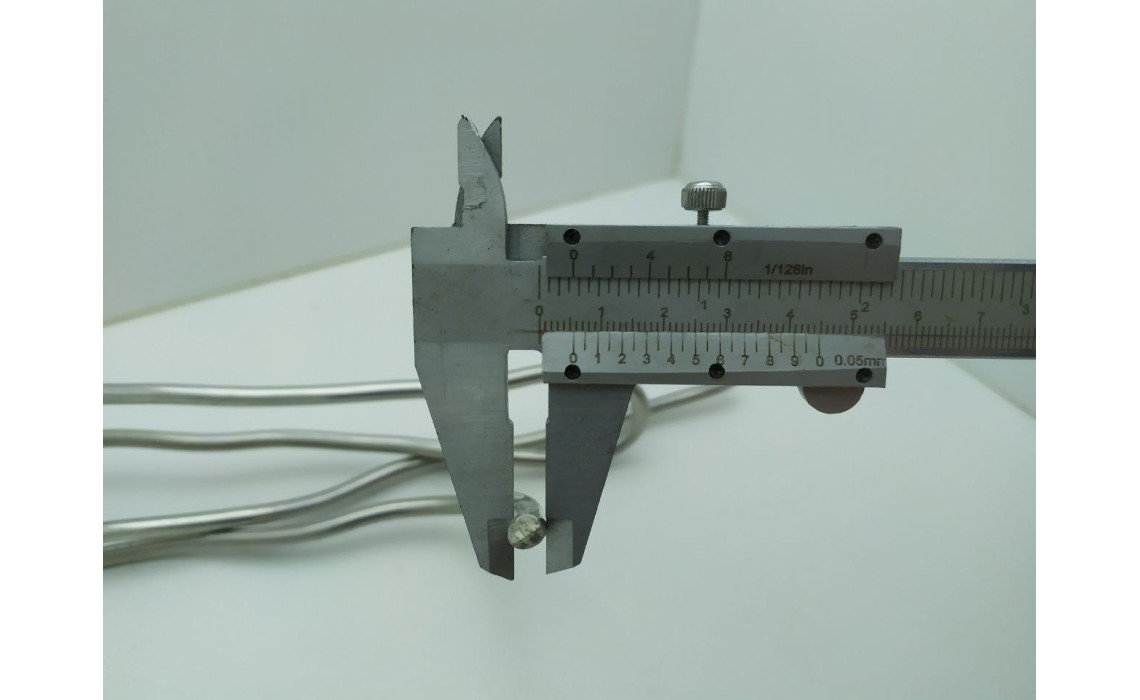

When working with equipment operating from a 220/380 V system, the cable conductor diameter also plays an important role. It is necessary to ensure that the conductor diameter is sufficiently large to provide a reliable connection and minimize energy losses.

Below are examples of cable cross-section selection tables for various types of equipment.

Cable cross-section selection table for lighting fixtures:

| Fixture Power | Line Length | Cable Cross Section |

| 100 W | 5 m | 1.5 mm² |

| 250 W | 10 m | 2.5 mm² |

| 500 W | 20 m | 4 mm² |

Table for selecting cable cross section for household appliances:

| Appliance Power | Line Length | Cable Cross Section |

| 1 kW | 10 m | 2.5 mm² |

| 2 kW | 20 m | 4 mm² |

| 3 kW | 30 m | 6 mm² |

Table for selecting cable cross section for power tools:

| Tool Power | Line Length | Cable Cross Section |

| 500 W | 5 m | 1.5 mm² |

| 1 kW | 10 m | 2.5 mm² |

| 2 kW | 20 m | 4 mm² |

So, to calculate the diameter (cross-sectional area) of a copper or aluminum cable based on its power, the following conditions should be taken into account:

- The power supply voltage - an important factor that affects the choice of cable diameter. For a low-voltage power system (up to 1000 V), the cable diameter can be smaller than that for a high-voltage system (over 1000 V).

- The distance between the source and the consumer - another factor to consider when calculating the cable diameter. The greater the distance, the greater the cable resistance and the larger the diameter required.

- The power in kilowatts of the consumer - the main parameter used to calculate the cable diameter. The higher the power, the larger the cable diameter should be.

- The type of cable - copper or aluminum. Copper cable has higher electrical conductivity, but its cost is higher than that of aluminum cable. When using aluminum cable, the diameter should be larger than that of copper cable.

- The temperature regime - another factor to consider when calculating the cable diameter. If the cable operates at elevated temperatures, its diameter should be larger than that under normal conditions.

Based on these conditions, the diameter (cross-sectional area) of a copper (Cu) or aluminum (AL) cable can be calculated based on its power. This requires using special tables and formulas that take into account all the factors mentioned.

It should be noted that these tables are only recommendations, and for an accurate determination of the cable cross section, it is advisable to consult a specialist. However, by choosing the correct cable cross section, the performance of electrical equipment can be significantly improved.

Cables and wires are an integral part of any electrical system. They transmit electrical energy from the power source to the consumer, making them an important component in any construction. One of the most important parameters of cables and wires is the cross-sectional area of the conductor, which should be selected considering several factors, including the power of the electrical system.

The tables for selecting cable cross section based on power are very convenient for those who are not experts in the field of electrical engineering. They help choose the right cable with the required conductor cross section based on the desired power of the electrical system and the cable length. This saves time and resources on purchasing and installing cables.

To select the correct and necessary cable cross section, several factors need to be considered, including the power of the electrical system, the cable length, the type and number of conductors, and the operating conditions. In addition, the chosen cable diameter should comply with the requirements of all relevant regulations, such as the Electrical Code (NEC) and others.

When choosing a cable, it is important to consider its allowable current load, which is determined by its cross-sectional area and conductor material. The higher the power of the electrical system, the larger the cross section the cable should have. With too small a cross section, the cable may experience overload, while with too large a cross section, power losses may occur.

Thus, the tables for selecting cable cross section based on power are a convenient tool for choosing the right cable with the required conductor cross section. They help save time and resources, and also ensure the reliability and safety of electrical systems. If you are planning to install electrical wiring in your home or office, be sure to use tables for selecting cable cross section based on power.

On our website, you can find information about the amount of copper in a cable depending on its diameter.

-262x197.jpg)

-262x197.jpg)

-262x197.jpg)